General

To understand the workings of a player piano, it is

necessary to first understand the key component parts and how they

are arranged within the instrument. A basic appreciation of the standard

upright piano action is also desirable. To see cross-sectional views

of a typical player, click on the thumbnail images below.

The

Roll Playing System

The player mechanism, typically referred to as the

'pneumatic stack', is located in the upper portion of the instrument

and connected to the piano action by series of push-rods. For each

note of the piano, there is a small pneumatic, a valve

assembly, a soft flexible leather pouch and a bleed.

The tracker bar has a row of equally spaced holes, each of

which is connected to a channel, via a small pipe. The chamber

is kept under vacuum by the foot operated bellows. The pneumatic

is connected to the piano action by a simple linkage.

The diagram below shows the whole assembly, firstly in resting and

then playing positions.

When

a roll perforation passes over a tracker bar hole, air is admitted,

causing the pouch to move upwards under suction inside the chamber.

The valve rises accordingly, uncovering the top of the chamber and

resting against its upper seat. This in turn connects the

pneumatic to the vacuum supply, forcing it to collapse under atmospheric

pressure and to operate the piano action.

The

bleed, which connects the channel to the chamber, allows the pouch

to assume its correct resting position after a note has finished

playing, by equalising the pressure above and below. The diameter

of the bleed is necessarily much smaller than that of the corresponding

tracker bar hole.

The

take-up spool, which is driven by an air

powered motor, transports the music roll over the tracker bar

at a speed that may be varied by means of a control lever. The tempo

of the music is unaffected by variations in the force at which the

pedals are operated, due to the presence of a governing device.

Large

diameter rubber hoses provide a connection between the main bellows

and pneumatic stack, in addition to other auxiliary devices. Rubber

tubing of small diameter is also used throughout, particularly in

the case of the tracker bar, each port of which has an individual

connection to its corresponding valve assembly.

The

Exhauster Bellows

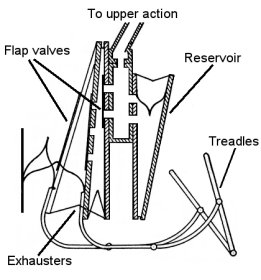

The

purpose of the exhauster bellows is to provide suction, which is the

motive force for virtually all player systems. Located in the lower

section of the piano, it usually consists of a large bellows

assembly connected to two foot treadles. The bellows are of wooden

construction, covered with heavy duty rubberised cotton cloth. The

purpose of the exhauster bellows is to provide suction, which is the

motive force for virtually all player systems. Located in the lower

section of the piano, it usually consists of a large bellows

assembly connected to two foot treadles. The bellows are of wooden

construction, covered with heavy duty rubberised cotton cloth.

As the

exhausters are alternately opened and closed by the action of the

feet upon the treadles, air within the system is exhausted

into the atmosphere. This naturally has the effect of lowering the

pressure within the player mechanism. The purpose of the external

leather flap valves is to allow the exhausters to discharge

the air extracted during the forward stroke of the treadles. Upon

the return stroke, the internal valve prevents any feeback of air

to the bellows system. The reservoir provides a necessary measure

of equalisation for the vacuum level within the player mechanism.

The

more sophisticated and fully automatic 'reproducing' pianos, described

later, utilise an electrically operated suction pump instead.

Auxiliary

Devices

Most players also incorporate a number of auxiliary devices,

the most common of which is a system that keeps the music roll in perfect

alignment with the tiny holes of the tracker bar.

Others

include a means of automatically operating the soft and sustain pedals

of the piano from perforations within the roll. Another popular feature,

known in Aeolian terminology as the 'Themodist', allows selected notes

to be accented, a concept known as 'theming' and also provides some

control over the dynamics of the music in general.

|